High-Performance Heat: The New Challenge for Data Centers

Demand for computing power for AI, HPC, and generative AI workloads is skyrocketing globally and Indonesia is no exception. As server density increases, managing heat becomes a critical issue for data center operators that must maintain energy efficiency and keep their PUE low.

This rising pressure leads to one essential question:

Can Liquid-to-Liquid (L2L) Cooling enable Indonesia to build more efficient, energy-conscious, and AI-ready data centers?

This topic was explored in depth on the Nusantara Podcast with three industry experts:

- Andi Terahady – ICT Sales Director, PT. Delta Electronics Indonesia

- Ir. Adam Bahfen – Principal Mechanical Engineer, Data Center Provider

- Hosted by Ariyohana Saraswati – Indonesia Head Account, Willowmore Pte. Ltd.

What Is Liquid-to-Liquid (L2L) Cooling?

(LSI: Liquid Cooling Indonesia, L2L cooling technology)

Liquid-to-Liquid Cooling is a next-generation cooling technology that uses liquid coolant to absorb heat directly from the processor through a cold plate. The captured heat is then delivered to a Cooling Distribution Unit (CDU) and exchanged with the facility’s primary cooling loop.

Figure 1. Liquid-to-Liquid (L2L) Cooling workflow: Cold Plate → Coolant Loop → CDU → Chilled Water → Heat Rejection.

In an L2L system, heat generated by CPUs/GPUs is absorbed by the cold plate and carried through the coolant loop. The CDU then transfers this heat to the facility’s chilled-water system. This process enables faster and more stable heat removal compared to traditional air cooling.

With a shorter and more direct heat-transfer path, L2L Cooling significantly boosts energy efficiency. Its ability to handle extremely high heat density makes it highly suitable for AI, machine learning, and high-performance computing (HPC) environments.

After understanding how it works, the next question emerges:

Why is this technology becoming increasingly vital for Indonesia’s data center landscape?

Why Liquid-to-Liquid Cooling Matters for Indonesian Data Centers

1. Server Power Density Is Rising Rapidly

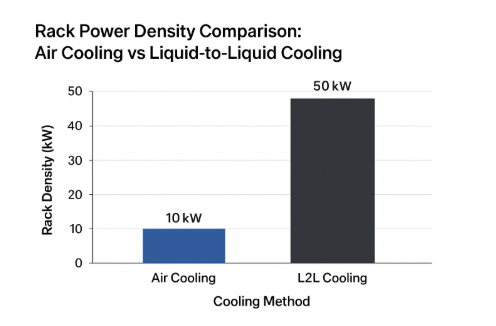

Figure 2. Rack Density Bar Chart

AI and HPC servers can reach 40–50 kW per rack, far beyond the 8–10 kW limits of traditional air cooling. L2L Cooling enables consistent and rapid heat removal, allowing data centers to maintain efficiency even as computing loads surge.

2. Lowering PUE and Supporting Energy Regulations

Most Indonesian data centers still operate at PUE 1.6–1.7.

With L2L Cooling, achieving PUE < 1.3 becomes far more realistic. This matters because:

- The government is pushing national energy efficiency

- ESG and sustainability targets are becoming global standards

- Hyperscale players demand low PUE as the minimum operational baseline

3. A More Sustainable Cooling Strategy

Indonesia cannot rely on free cooling like temperate countries. L2L Cooling reduces energy consumption significantly without depending on specific climate conditions, helping operators cut carbon footprints and move closer toward net-zero goals.

With this context, the next question naturally arises:

Is L2L Cooling strong enough to support Indonesia’s generative AI ambitions?

Can L2L Cooling Accelerate Indonesia’s Generative AI Development?

The short answer: yes — with several critical prerequisites.

L2L Cooling is not merely a cooling method, but a foundational element for building a competitive AI ecosystem.

1. AI Infrastructure Requires Extremely High Compute Density

Developing generative AI requires top-tier hardware such as:

- NVIDIA H100/H200 GPU racks

- TPUs or AI-specific ASICs

- National-scale HPC clusters

Such density can only be reliably cooled with Liquid-to-Liquid systems, as air cooling cannot handle extreme thermal loads.

2. L2L Cooling Is the Gateway to Truly AI-Ready Data Centers

With superior heat-transfer efficiency and lower energy usage, L2L:

- improves infrastructure stability

- supports scalable AI deployments

reduces operational costs

3. ROI Becomes Clearer as the AI Ecosystem Grows

As noted by Ir. Adam Bahfen, L2L Cooling comes with a high CapEx.

However, ROI becomes much more visible when AI workloads stabilize and demand rises — driven by startups, enterprises, and the public sector.

Challenges of Implementing Liquid-to-Liquid Cooling in Indonesia

Despite its potential, widespread adoption remains limited due to structural barriers:

1. High CapEx and Uncertain ROI

Switching to L2L Cooling is a major investment, causing many local providers to wait for clearer AI market signals.

2. Complex Installation Requirements

The system requires precision piping, corrosion-resistant materials, and contamination-free installation. Even minor errors can cause downtime, making the integration riskier.

3. Limited Local Engineering Expertise

Most engineers are experienced with traditional CRAC/CRAH systems.

L2L Cooling requires new skills, including:

- thermal design

- hydraulic calculations

liquid-system commissioning

4. Long Equipment Lead Times

CDUs, manifolds, and other components often require 3–4 months, causing project delays.

5. Rapid Technology Evolution

Vendors release new generations annually, raising concerns that today’s investment might become obsolete within 2–3 years.

Liquid Cooling vs. Air Cooling: A Quick Comparison

Aspect | Air Cooling | Liquid-to-Liquid Cooling |

Rack Density | 2–10 kW | 30–50 kW |

PUE Efficiency | Moderate | Higher efficiency |

CapEx | Lower | Higher |

Maintenance | Frequent | Less frequent |

AI Readiness | Limited | Highly AI-ready |

The Outlook for Liquid-to-Liquid Cooling in Indonesia

Despite the challenges, the industry direction is increasingly clear.

1. Hyperscalers Will Lead Early Adoption

Their compute needs are exploding, making L2L the most practical solution. Once hyperscalers adopt it, local providers typically follow.

2. Local Providers Are Preparing AI-Ready Racks

Several Indonesian data centers are now deploying GPU and HPC clusters — a strong indicator of growing demand.

3. Energy and ESG Regulations Are Tightening

L2L Cooling directly supports national goals for sustainable digitalization and reduced emissions.

4. Collaboration Across the Ecosystem Is Expanding

Vendors, consultants, universities, and operators are increasingly discussing green cooling solutions, opening opportunities in:

- local engineer training

- next-generation cooling standardization

- AI-ready infrastructure research for tropical climates

Conclusion: Is Indonesia Ready?

The arrival of Liquid-to-Liquid Cooling marks more than a technological upgrade — it is a strategic step toward Indonesia’s digital future, enabling:

- national generative AI infrastructure

- more efficient and sustainable data centers

- better energy optimization

- readiness for global AI workload growth

L2L Cooling may not yet be the standard, but it is undeniably becoming the foundation of modern, AI-driven data centers.

The question is no longer “Do we need it?”,

but “When are we ready to take the leap?”

For more details, listen directly to the podcast on YouTube Nusantara Academy and don’t forget to register for training by contacting https://wa.me/6285176950083